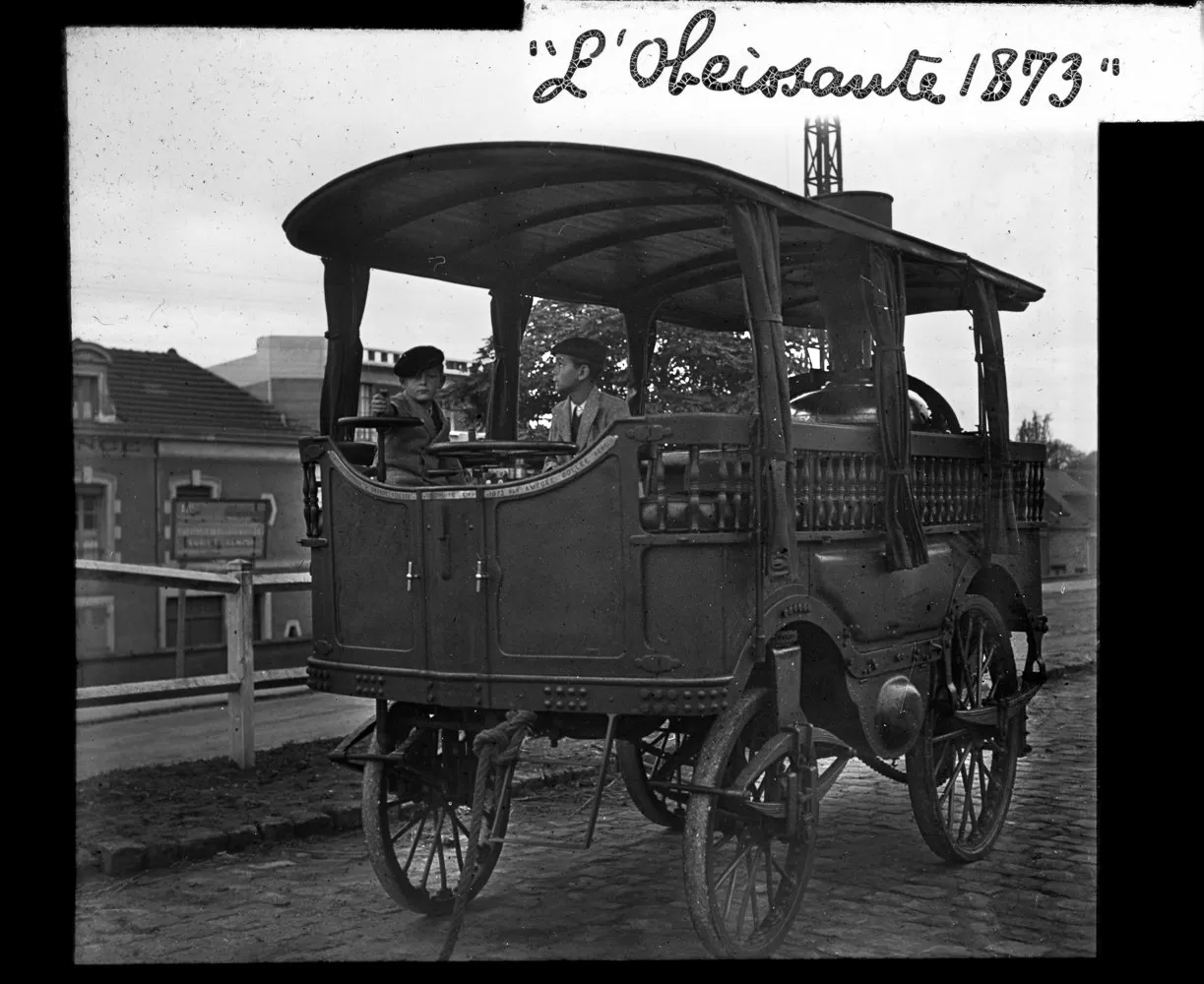

Manufacturing capabilities

capabilities

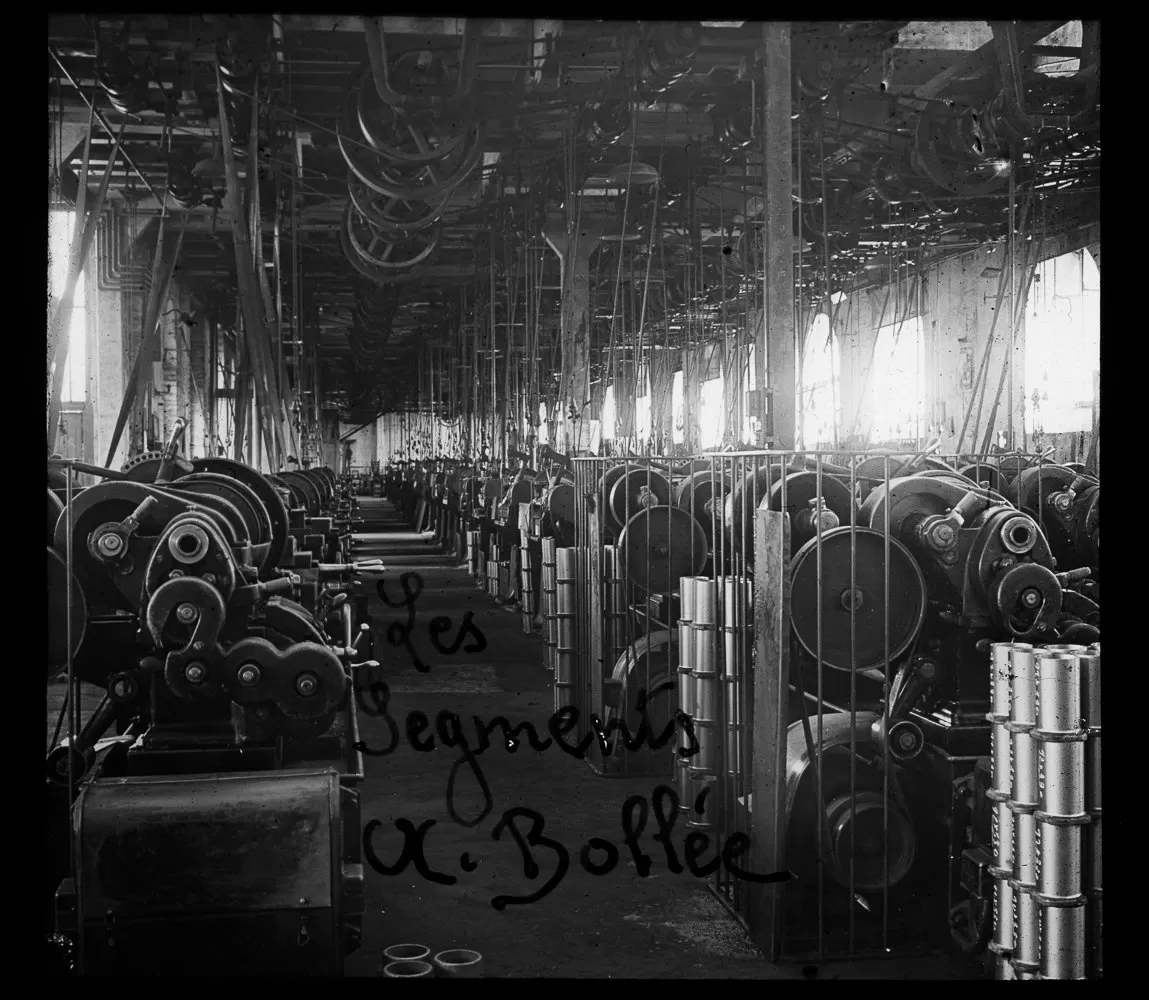

Our workshops are equipped to produce rings from 8mm diameter up to 2100mm.

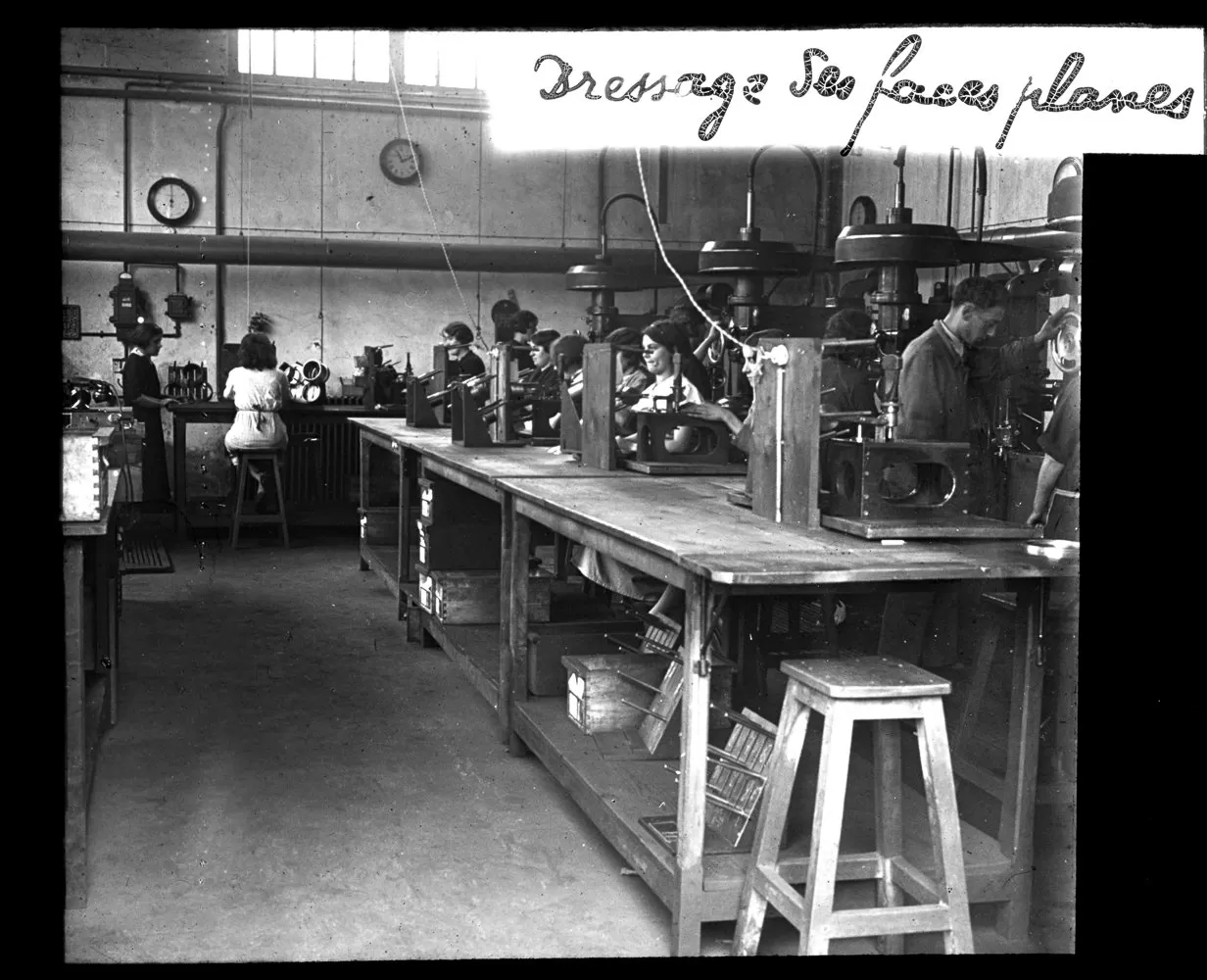

We make all types of rings: rectangular, conical, bull nose, Scraper ring with and without shoulder, oil control ring….. In the same manner, all the variants of cross section are available: vertical, oblique, with notches, step cut, bayonets …..

The material base for our rings is cast iron but we also work with Steel, Bronze, cobalt based metals…. Consult us with your requirements.

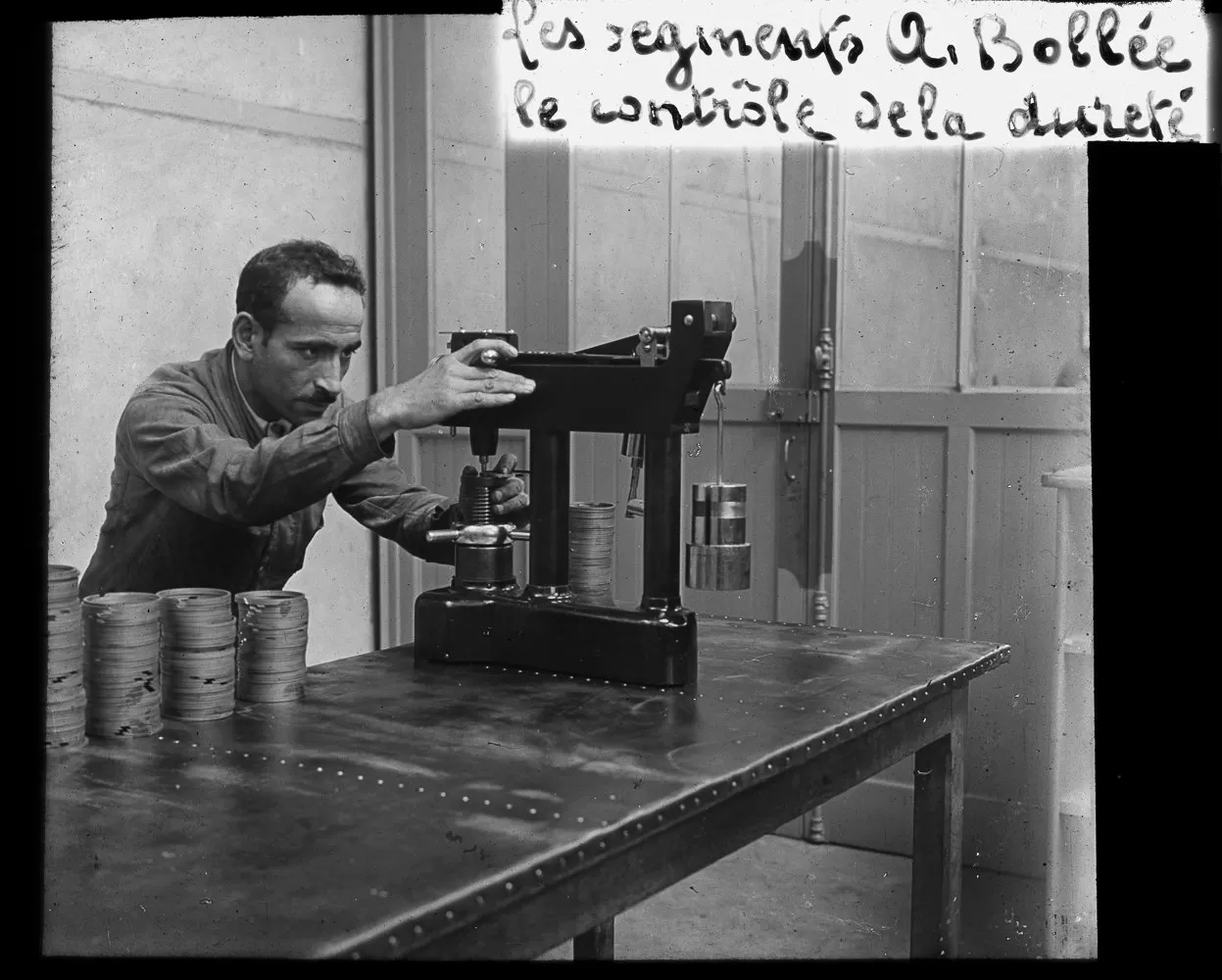

Different treatment and coating can also be applied to the rings depending on the requirements, as in: Chrome coating, vacuum or atmosphere heat treatment.

The flexibility in the organisation as well as our machining park allows us to make one piece and volume production of 40000.

The manufacturing lead times go from 24h up to 10 weeks depending on the type of ring and availability of the raw material. All is made to order (open). More than 40000 references of all makes are recorded in our files.

We put everything in place to adapt to your requirements (technical, reactivity, price).

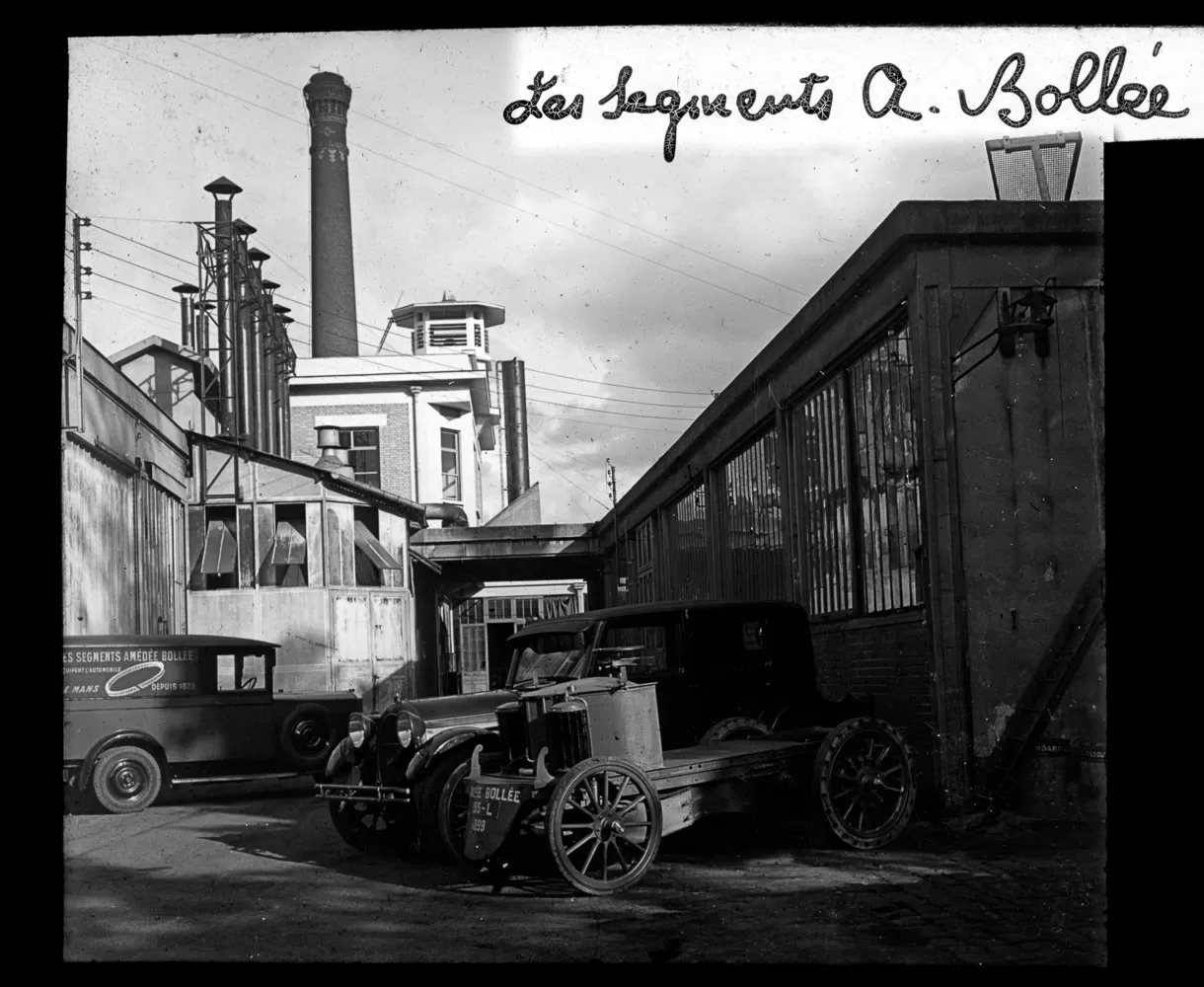

Most of the alloys are sourced from Cronite Mancelle. This foundry is located on the same site and is specialised in Heat resistant alloys, the rings. The foundry holds the required quality standards to match the most severe market requirements.

The rest of the materials are sourced on the French Market from quality suppliers. Our team can help you design and manufacture to your requirements, Do not hesitate to consult us for more information.