Specific pressure

The sealing of the segment is determined by the proper fit of the specific pressure of the segment on the cylinder and by the good resistance of the segment to wear.

The measurement of specific pressure remains within the scope of the laboratory study. Therefore, the measurement of the tare, that is to say the tangential force (Ft) or the diametric force (Fd), is used to understand this. Fd = Ft x 2.21 for E = 100,000 N/mm2. This measure is indicative because the tangential force distribution is not uniform on the periphery or on the height of the segment. On the periphery, the pressure is not the same if measured at 15°, 90°, or 180°. On the axial height, the presence of bevels, inner shoulders or a non-symmetrical section (Type M) will cause significant variations in pressure.

For segments of nominal diameter greater than or equal to 40 mm, Ft should be measured.

Below 40 mm, the ISO standard recommends the measurement of the free opening. The tangential force of the segment (Ft) is determined by several parameters:

- Material: It determines the modulus of elasticity (E). The standard untreated grey cast iron (FGL F55) has a modulus E= 100000 N/mm2. The spheroidal graphite cast (FGS F58) has an E module = 160,000 N/mm2

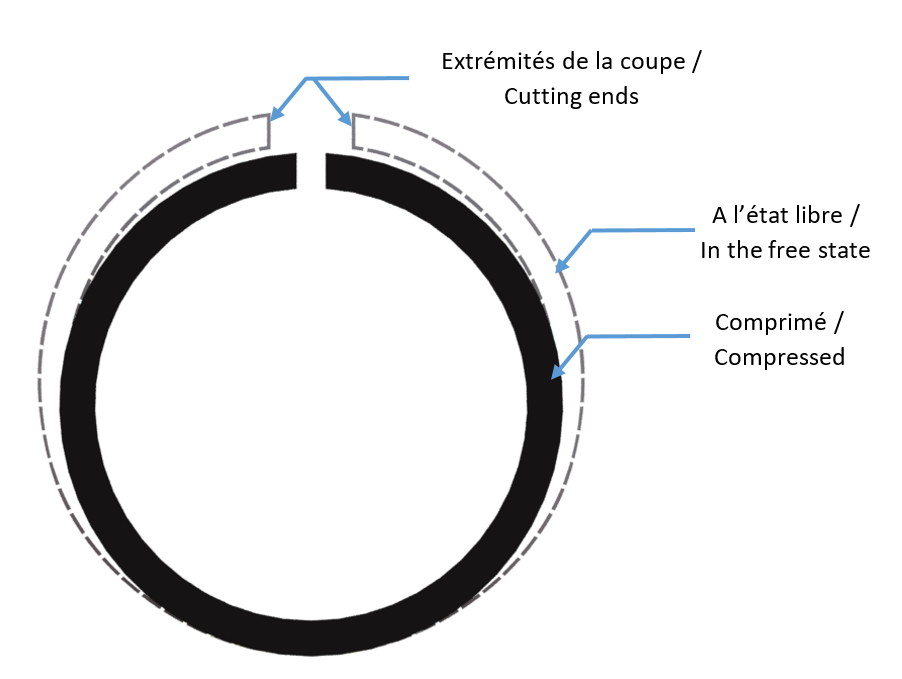

- Dimensions: Ft varies with the diameter dl, the bevel or shape options brought to the peripheral reach of the segment (conical shape, curved, bevel KA...). The tangential force varies in proportion to the cube of the radial thickness. This explains the use of some engine manufacturers on the inner shoulders to make a segment R IW behave as an M segment, under the only dynamic stress of the specific pressure. Finally, the free opening (m) given to the segment will also have a significant impact. In general, the free opening m is equal to 12 to 15% of the nominal diameter.

- Coatings: the possible chrome belt affixed to a segment causes a drop in the tangential force estimated at 10%.

In operation, the specific pressure P is only rarely checked. Indeed, the working segment receives an additive pressure on its inner surface due to the pressure of the compressed fluid that enters the bottom of the groove from the wax of the leak to the cut and the play on the flat staves. It is therefore considered that the effective pressure is often much higher than the nominal pressure.