Surface treatments are techniques used to improve the properties of materials and extend their service life. They can be used to protect against corrosion, improve aesthetics, strengthen wear resistance and facilitate surface cleaning. Surface treatments are commonly used in industry, including the aerospace and automotive sectors. With a variety of techniques available, surface treatments can be adapted to many types of materials to meet a wide variety of needs.

Here are some surface treatments we do for our customers:

Phosphating:

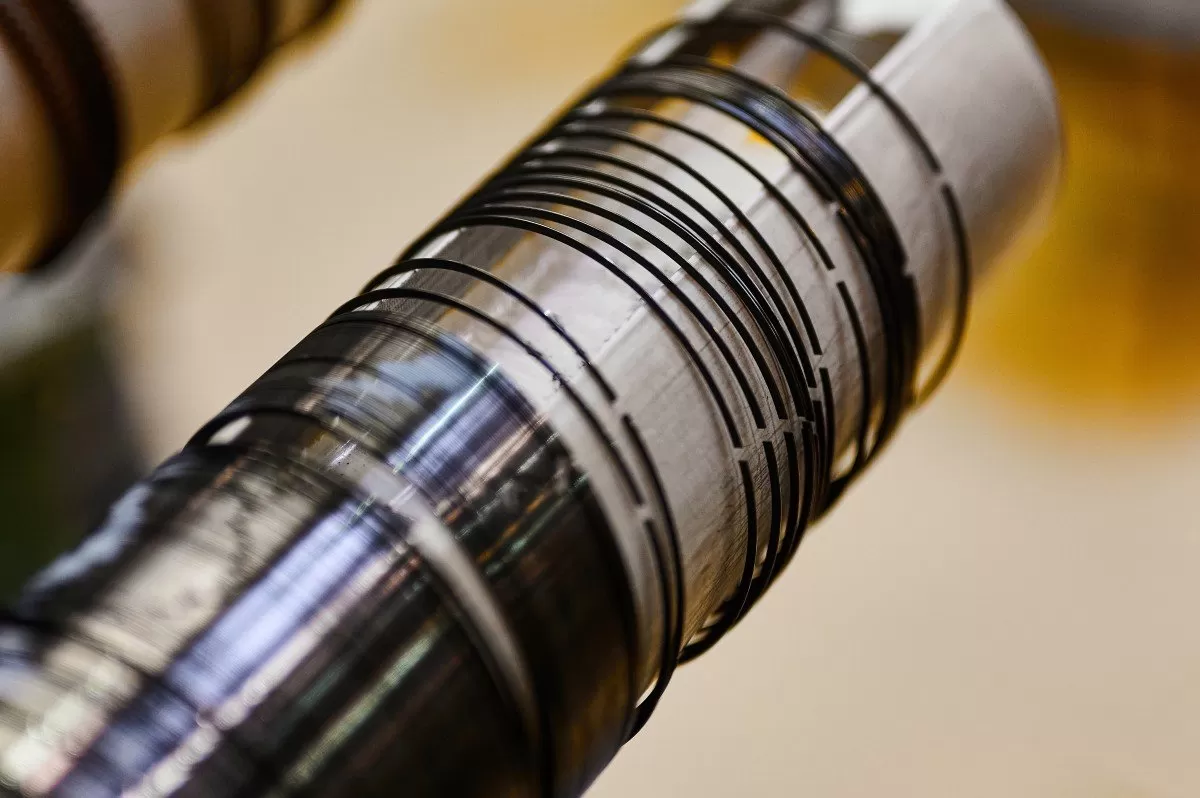

Phosphating is a surface treatment technique commonly used in our manufacturing process. It is used to improve corrosion resistance, adhesion of paints and lubricants, as well as sealing of metal segments. This process involves the use of an acid solution containing phosphate salts and wetting agents. The sealing segments are immersed in this solution, which causes the formation of a phosphate layer on their surface.

This phosphate layer, made of zinc or manganese phosphate crystals, adheres only to the metal surface. Commonly used in our manufacturing process, phosphating accelerates safety during the run-in time. The phosphate layer wears out more easily than the base materials, thus reducing break-in time. The particles extracted from the ferrous layer, because of their hardness, serve as "breaking-in abrasive". These two layers, together with the nitride layer, have a determined resistance against the formation of burns and are used with good results when the level of tendency to burn is relatively low

Chrome plating:

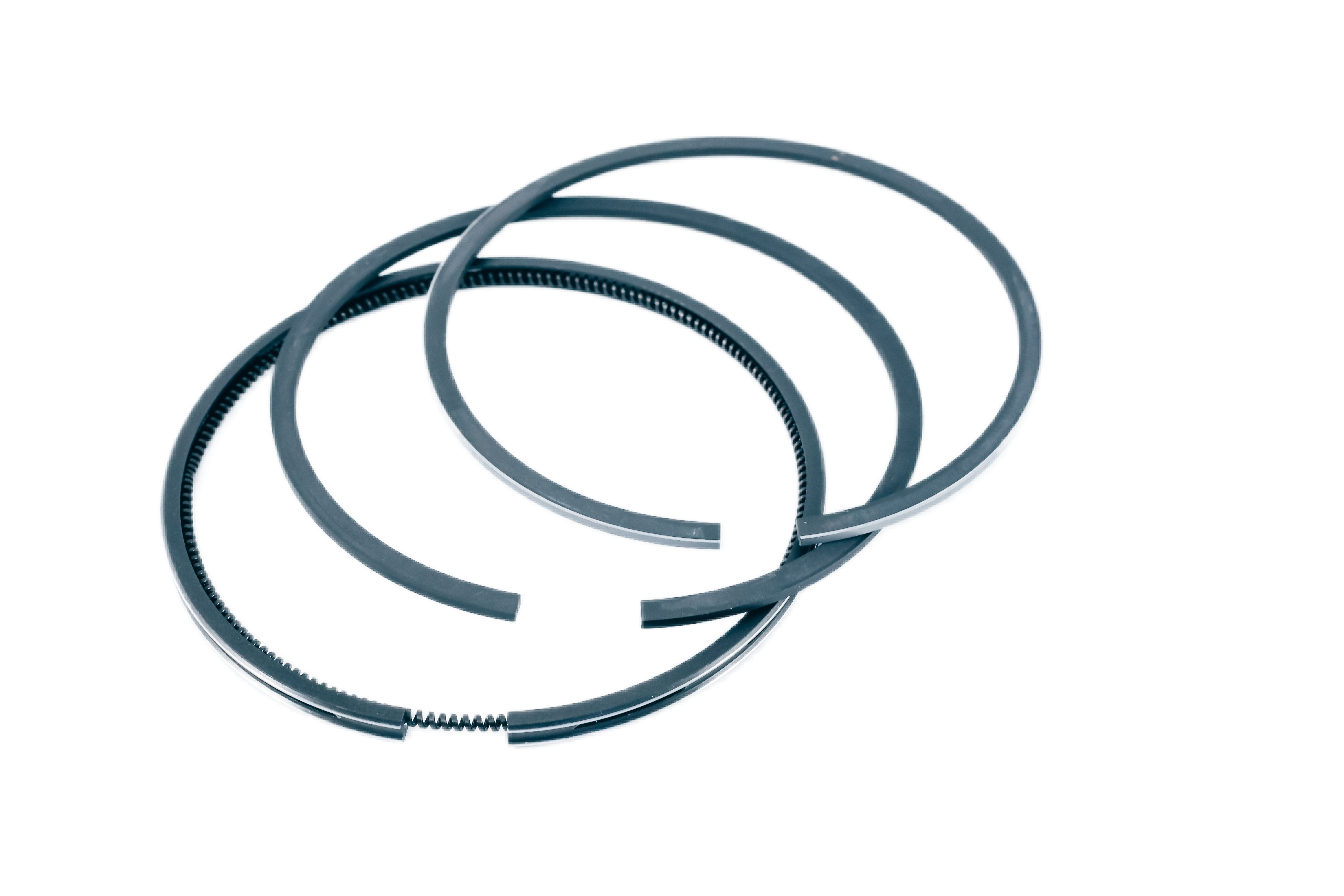

Chrome plating is a surface treatment technique commonly used for metal sealing segments. This technique involves applying a thin layer of chromium to the surface of the sealing segments to improve their corrosion resistance, durability and aesthetic appearance. The chromium plating process involves the use of an electrolytic chromium bath, in which the segments are immersed. The chromium ions are then deposited on the metal surface of the sealing segments, creating a hard and uniform chromium layer.

The hard chrome coating offers high wear resistance. It is distinguished by its high resistance to burns, placing it above uncoated segments and even treated segments. In general, the most significant wear occurs at the high dead point, especially on the first piston segment, due to adverse slip conditions, gas pressures, heat and corrosion caused by combustion residues.

Therefore, as a rule, only the bearing surfaces of the first segment are chrome-plated. In extreme conditions such as heavy dust or heavy oil use, the second segment is also often chrome-plated. Experience shows that the chrome rings reduce the wear of the bearing surface of the cylinder by about 50% and that of all the piston rings by about 30% compared to the chrome-plated rings.

The high wear resistance of the chromium layer has the natural consequence that the chrome segments move slower than the non-chrome segments.

Sulphuring:

Surface sulphuring is a thermochemical treatment technique used to strengthen the surface properties of metal sealing segments. This technique involves the use of a sulphur bath, in which the segments are immersed at high temperature to form an iron sulphur layer on the surface. This iron sulphur layer improves the wear resistance, corrosion resistance and durability of the sealing segments.

Surface sulphuring is commonly used in the automotive and aerospace industries to improve the life of parts exposed to extreme environments. This technique can also be used to strengthen the fatigue resistance of mechanical parts subjected to cyclic stresses.

Surface sulphuring has several advantages over other surface treatment techniques.

Silver Plating:

This treatment is mainly used for its conductive or electrical properties but in our application it is used for its good friction resistance and resistance to hot binding.

Silver is deposited on multiple metals such as steel, stainless steel, brass, copper alloys, nickel, titanium, aluminium especially with a thickness between 1 to 30 µm.

DLC processing:

The strength of the DLC (Diamond Like Carbon) treatment is its good resistance to friction and its hardness is comparable to that of the diamond, hence its name.

Its friction coefficient is almost 10 times lower than that of a conventional surface treatment on steel, which guarantees unprecedented scratch resistance.

The properties of this surface treatment are: