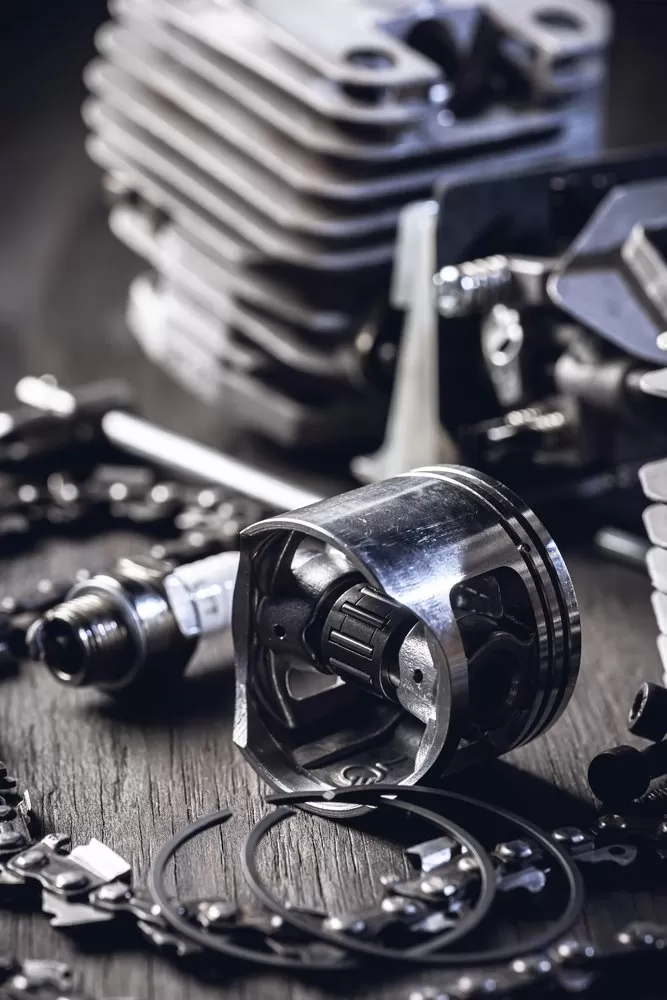

Moteur 2 temps

Dans l'industrie des moteurs 2 temps, les segments d'étanchéité jouent un rôle clé pour assurer une étanchéité fiable et optimale entre les différentes parties du moteur. Parmi les différentes coupes utilisées, la coupe R, la coupe NH et la coupe NE sont parmi les plus couramment utilisées.

La coupe R, fait référence à une coupe droite appliquée sur le segment d'étanchéité. Cette coupe simple et rectiligne permet d'assurer une surface de contact plane et régulière entre le segment et les parois du cylindre, garantissant ainsi une étanchéité efficace et minimisant les fuites de gaz. La coupe R est utilisée dans les moteurs 2 temps pour assurer une compression adéquate du mélange air-carburant et une combustion efficace.

La coupe NH, également connue sous le nom d’encoche intérieur présente une forme en diagonale sur le segment d'étanchéité. Cette coupe permet d'optimiser l'étanchéité en fournissant une pression uniforme sur les parois du cylindre, réduisant ainsi les risques de fuite et évitant la rotation du segment dans son logement. La coupe NH est souvent utilisée dans les moteurs 2 temps pour améliorer les performances et l'efficacité globale du moteur.

La coupe NE, également connue sous le nom d’encoche latérale, présente une section en forme de trapèze ou de biseau sur le segment d'étanchéité. Cette coupe est conçue pour éviter la rotation du segment dans son logement et pour faciliter l'insertion et le retrait du segment dans le cylindre, réduisant les risques de dommages lors de l'assemblage ou de la maintenance. La coupe NE est couramment utilisée dans les moteurs 2 temps pour assurer une installation et un ajustement faciles du segment d'étanchéité.

Dans le secteur des moteurs 2 temps, les segments d'étanchéité avec les coupes R, NH et NE sont utilisés dans différentes applications, des moteurs de petite taille aux moteurs plus gros et plus puissants. Ces segments garantissent une étanchéité fiable, minimisent les pertes de compression et contribuent aux performances optimales du moteur 2 temps.