The aim of our company is to bring in a sustainable manner, les best possible service to its customers, with prejudice to the volumes required or their geographical location.

To achieve this, our commercial department will always seek for maximum details on the destines application of our products and will take care to establish with the technical department the required checks to offer a product meeting all customer technical requirements and guaranty the optimum functionality.

The commercial department is also responsible for tracking the orders and respecting supply as agreed.

The quality of the contact pressure all around the ring is achieved by the evenness of the radial thickness.

On an engine, the running in of the ring in and by the cylinder is quite quick. In other applications, for example hydraulic, there is none or little; the flat face located in the groove has no running in. The condition of the surface on the ring must therefore be adapted to the application. For this case, we can only advise you to communicate to us the application of the rings ordered so that we can optimises the parts to their environment.

Respect of the requirements in terms of flatness, parallelism, squareness etc… is vital.

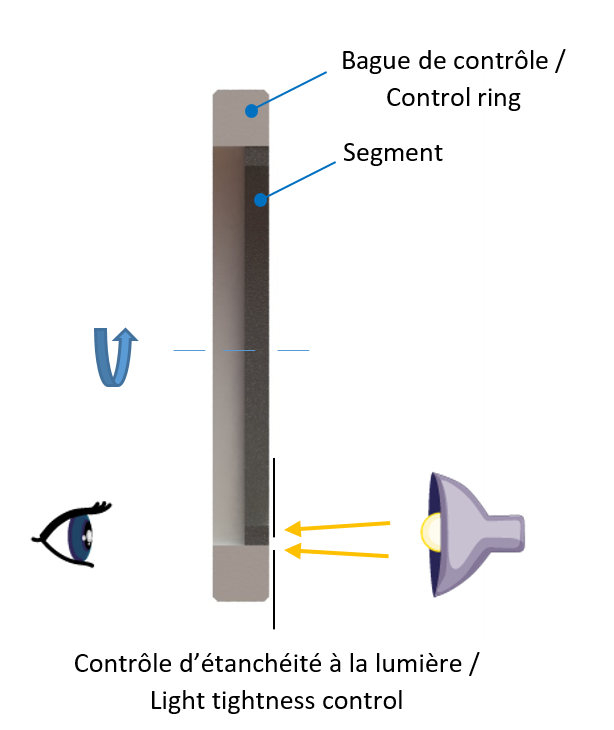

The manufacturing control is integrated at every stage of our manufacturing process, including the circularity measuring device, the light sealing control and the tangential force measurement.

Our quality service ensures that our products are to the standards stipulated by our customers.

The SPC control can be done on request subject to a price premium.

Refer to ISO 6621-5 norm for further details.